What is uv printer?

UV printing is a form of digital printing that uses ultra-violet lights to dry or cure ink as it is printed. As the printer distributes ink on the surface of a material (called a "substrate"), specially designed UV lights follow close behind, curing - or drying - the ink instantly. Originally developed for quickly drying gel nail polishes during manicures, ultraviolet light applications quickly expanded into industrial and commercial markets. Because the UV lights cure any printed ink immediately, the dots of wet ink do not get a chance to spread out once printed, resulting in much finer detail. In addition, UV cured inks are weather-resistant and offer increased resistance to fading. This curing process is more environmentally friendly as it produces few VOC’s, odor, and heat. UV curing also allows the flatbed printer to be used with nontraditional materials like acrylic or aluminum. In fact, this UV flatbed printer is compatible with most substrates up to 2” thick!

UV Flatbed Printer Capabilities at a Glance

Large Format Graphics

- Up to 4’ x 8’ - and 2” thick

- Compatible with both rigid and flexible materials - including Acrylic, ABS, Coroplast, Aluminum, Foam board

Second Surface Printing

- Printing on the back of a transparent material

- Gives the appearance of depth & added gloss

- Added durability/longevity of graphics

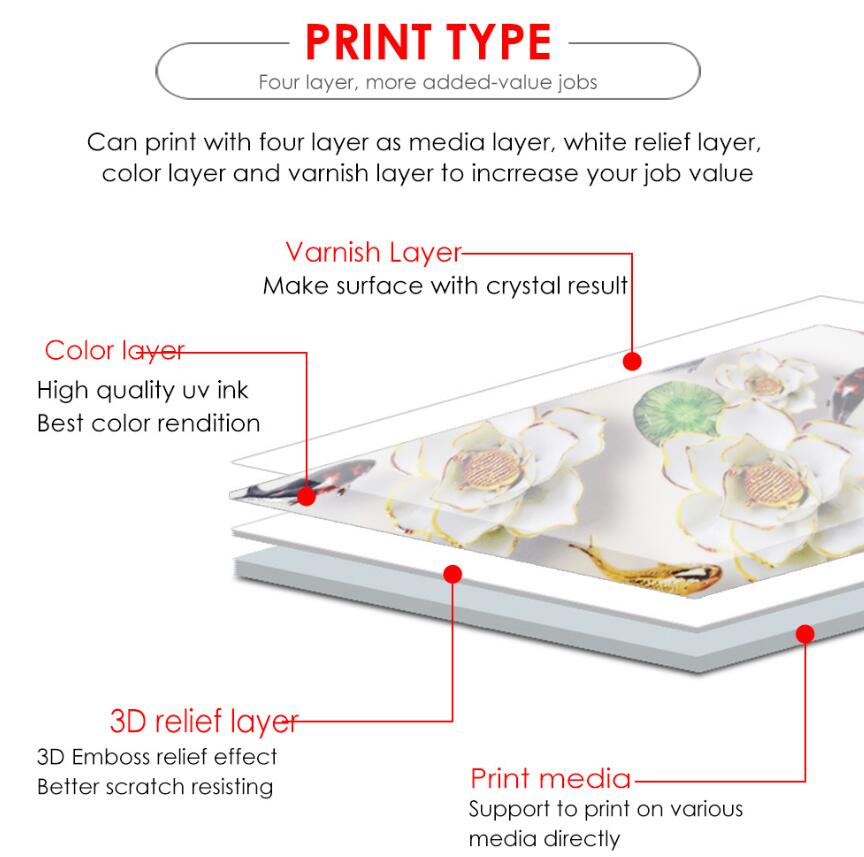

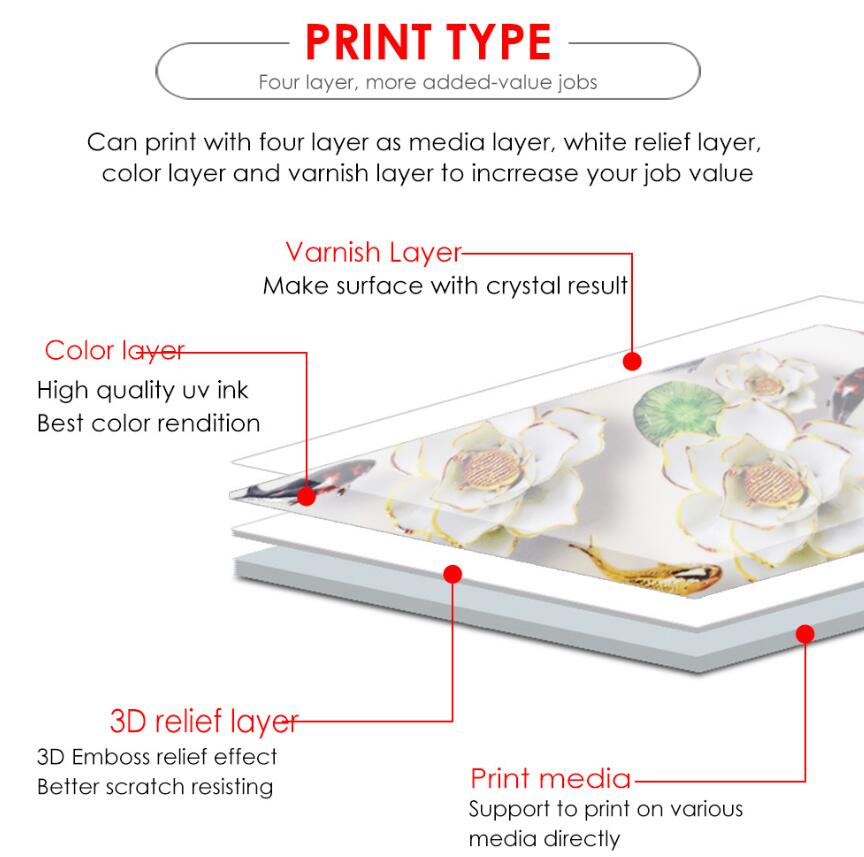

Treble Layer Printing w/ White Ink

- Layers of white ink under color ink

- Increases vibrancy of graphics

- Ideal for transparent materials

- Print varnish glossy on the top of white for crystal mirror shining effect.

Varnish glossy ink

- High gloss

- Ability to add texture with clear ink only added to certain areas of the print

-

Why We Love UV Printing

The introduction of the UV flatbed printer is a great addition to our custom production abilities. Displays2go’s current in-house printing capabilities include vinyl/digital heat press, silk screening, and solvent digital printing. The flatbed design of the UV printer allows us to produce the same high quality work as our solvent printers, only on thicker substrates! Our silk screening machinery does accommodate thicker materials, like acrylic, however these orders typically come with minimum order quantities which might not meet the needs of every customer. This same high quality output with added flexibilty makes the new printer a great companion to our current production abilities!

UV flatbed printers feature some of the most up-to-date printing technology on the market today. By bringing this technology to Displays2go, we’re bringing the very best in custom signage to our customers. As a result, we are now the largest POS displays company with this printing capability in house. It's exciting stuff! While many smaller sign shops offer UV printing services, Displays2go is the only leading POS provider to bring this printing technology to a national audience. This makes us a one-stop-shop for any and all business displays you might need!

(3D texture relief printing result by focus Galaxy-Jet X uv printer)

(Trible layer printed as white+color+varnish by focus uv printer)

Please visit this video to learn more about uv printing technology:

---Author: Focus inc engineer John Liu